The X3 is a powerful, three-way horn-loaded enclosure, designed for large-scale events. Through the use of six 1.7” (44mm) diaphragm, 1” (25mm) exit compression drivers and a bespoke waveguide, the acoustic centres of each drive unit are close enough to effectively create a horizontal line source. This line source not only provides seamless HF coverage right across the X3’s 20-degree coverage pattern but also allows predictable integration of multiple X3 enclosures. Both mid and low frequencies are also handled by horn-loaded systems to give unrivalled output SPL and system efficiency. The low frequency section uses a 4” (101mm) voice coil, 15” (381mm) neodymium drive unit loaded onto a horn nearly 1.5 metres in length. Due to the unique folding technique used in this system, the low frequency horn extends the useable frequency response higher than more conventional systems. Midrange frequencies are handled by an 8” (203mm) neodymium drive unit, loaded via a cylindrical phase plug onto an exponential/hyperbolic horn.

Due to the highly predictable horizontal dispersion pattern, X3 enclosures integrate seamlessly into arrays when required. The enclosure wall angle matches the dispersion angle which allows the X3 to be used in tightly-packed arrays – in this way, systems can be built from 20-degree “building blocks” making system design much simpler. Due to the 20-degree coverage pattern, the X3 is also ideal for use as side fills, centre fills or in/out fills for much larger arena shows. A variety of DSP presets are provided to give different voicings – allowing the use the X3 as a front of house system, side fills/infills or for shorter throw applications.

The enclosure is constructed from premium multi-laminate Birch plywood with stainless steel fixings throughout. The enclosure is finished in black impact resistant paint as standard, however RAL colour matching and weather protection options are available. The enclosure is fitted with a complete integral flying system, which allows tight-pack arrays to be assembled either flown or groundstacked. Also included are seven steel bar handles for ease of movement. Another unique feature is the drive unit test system – powered from a 9V battery – which disconnects the input connectors and passes a low voltage current through all eight drive units. Visual indication of electrical continuity is given on the rear panel in a graphical layout, providing a quick and simple fault-finding solution.

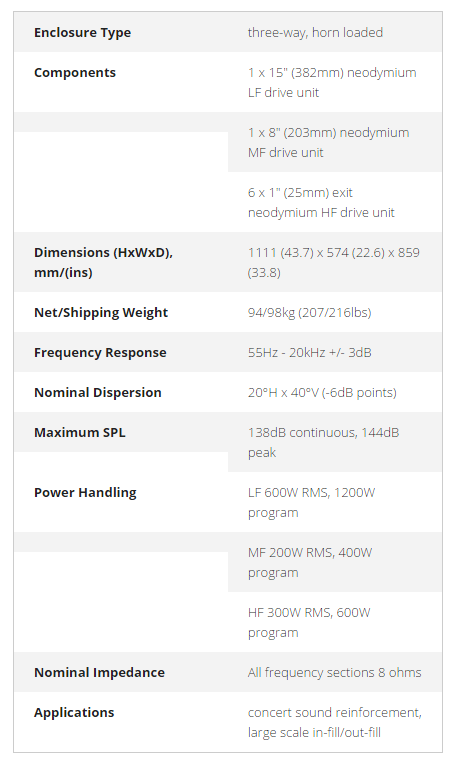

The X3 requires an external DSP active crossover unit, and three amplifier channels – one each for LF, MF and HF. These amplifiers should be capable of delivering a minimum of 1200W, 400W and 600W program respectively into an 8 ohm load. For best results, EM Acoustics AQ-10 amplifiers should be used.